Coronavirus Supply Chain Disruptions Kelloggs, Nike, HP

Coronavirus supply chain disruptions kelloggs nike hp – Coronavirus supply chain disruptions Kellogg’s, Nike, and HP faced highlight the fragility of global interconnectedness. This exploration delves into the specific challenges these giants encountered, from ingredient shortages to manufacturing bottlenecks, and analyzes their responses. We’ll uncover how they adapted, diversified, and ultimately navigated the pandemic’s impact on their respective sectors, and look at the lessons learned for the future.

This analysis examines the impact of the pandemic on Kellogg’s, Nike, and HP’s supply chains, considering the unique challenges each company faced. We’ll delve into their individual strategies for resilience, focusing on their mitigation efforts, and evaluating the long-term implications of these disruptions. Furthermore, we’ll analyze the similarities and differences in their approaches, drawing cross-industry comparisons and outlining industry-specific vulnerabilities.

Impact on Kellogg’s Supply Chain: Coronavirus Supply Chain Disruptions Kelloggs Nike Hp

The COVID-19 pandemic significantly disrupted global supply chains, impacting even large multinational corporations like Kellogg’s. This disruption necessitated rapid adaptation and innovative strategies to maintain operations and customer satisfaction. Kellogg’s, a major food manufacturer, faced unprecedented challenges in sourcing, production, and distribution, prompting them to implement crucial long-term adjustments to their supply chain.Kellogg’s faced considerable obstacles during the pandemic, including fluctuating ingredient availability, transportation bottlenecks, and labor shortages.

These disruptions directly affected production schedules and delivery timelines, impacting both Kellogg’s ability to meet consumer demand and its overall profitability. To ensure future resilience, Kellogg’s implemented a comprehensive strategy focusing on diversification, redundancy, and enhanced communication within the supply chain.

Ingredient Shortages

Ingredient sourcing became a critical challenge for Kellogg’s, as many agricultural producers faced disruptions and production limitations due to the pandemic. The global nature of the supply chain meant that shortages in one region quickly cascaded through the system. Kellogg’s responded by diversifying their sourcing channels, establishing relationships with multiple suppliers in different regions, and building buffer stocks of essential ingredients.

This diversification ensured a wider range of options in case of future disruptions.

Transportation Bottlenecks, Coronavirus supply chain disruptions kelloggs nike hp

The pandemic caused significant congestion in global transportation networks, leading to delays and increased costs for shipping raw materials and finished goods. Ports and warehouses faced immense pressure, leading to prolonged transit times. Kellogg’s proactively worked with transportation partners to identify alternative routes and streamline logistics. This included exploring rail and air freight options where appropriate, and optimizing inventory management strategies to reduce the impact of shipping delays.

Labor Issues

The pandemic significantly affected labor availability, leading to shortages in key roles, from factory workers to warehouse staff. Kellogg’s responded by implementing flexible work arrangements, providing training opportunities for existing staff, and attracting new talent to fill critical roles. This addressed the immediate labor shortages while also building a more resilient workforce capable of handling future disruptions.

Long-Term Adaptations

Kellogg’s recognized the need for long-term adjustments to their supply chain. A key adaptation was enhancing communication and collaboration with suppliers. This included developing more robust and proactive communication channels to enable real-time updates and problem-solving. Furthermore, they strengthened their relationships with key partners, building trust and mutual understanding for more effective collaboration.

Supply Chain Resilience Measures

Kellogg’s implemented various measures to ensure supply chain resilience, including building up safety stock levels for critical ingredients and finished goods. This buffer inventory mitigated the impact of unforeseen disruptions. They also invested in technologies like predictive analytics to better forecast demand and anticipate potential disruptions. These strategies provided Kellogg’s with the ability to respond quickly to evolving circumstances and maintain their supply chain integrity.

Financial Impact

The supply chain disruptions undoubtedly impacted Kellogg’s financial performance. While the precise figures are not publicly available, industry analysts noted a potential impact on revenue and profitability during the peak of the pandemic. The company’s ability to quickly adapt and mitigate the effects of the disruptions is crucial to understanding its overall financial resilience.

Impact on Nike Supply Chain

Nike, a global sportswear giant, faced significant disruptions to its supply chain due to the COVID-19 pandemic. The ripple effects were felt across various manufacturing hubs, impacting raw material procurement, production, and logistics. Understanding these challenges is crucial for evaluating the resilience of global supply chains and the adaptability of major corporations.

Manufacturing Strategies in Different Regions

Nike’s manufacturing strategies, heavily reliant on Asian hubs like Vietnam, Indonesia, and China, were severely impacted. The pandemic brought about lockdowns and disruptions in these regions, halting production and creating delays in shipping. In contrast, European manufacturing, though smaller in scale, experienced disruptions, although to a lesser extent. The varied impacts highlighted the risks associated with concentrated sourcing in specific geographical regions.

Raw Material Procurement, Manufacturing, and Logistics Challenges

Nike faced significant challenges in procuring raw materials. The pandemic led to factory closures and port congestion, causing delays in the delivery of crucial materials like leather, textiles, and synthetic fabrics. Manufacturing plants faced worker shortages and disruptions in the supply of critical components. Logistics, another crucial component, was also affected. Shipping delays and port congestion caused massive backlogs and delays in getting finished products to retailers and consumers.

These issues directly affected Nike’s ability to meet demand and maintain its supply chain’s integrity.

Supply Chain Diversification

To mitigate the risk of relying solely on Asian manufacturing, Nike started to diversify its supply chain. This involved exploring new manufacturing locations in regions like Southeast Asia and Europe. The diversification strategy aimed to reduce dependence on single points of failure and improve resilience. This shift demonstrates the growing importance of geographical diversification in mitigating risks associated with global supply chain disruptions.

Comparison of Pre-Pandemic and Post-Pandemic Supply Chain Strategies

| Pre-Pandemic Strategy | Challenges | Mitigation Strategies | Post-Pandemic Strategy |

|---|---|---|---|

| High concentration of manufacturing in Asia (primarily). | Vulnerability to regional disruptions (e.g., lockdowns, natural disasters). Limited flexibility in responding to unexpected events. | Implementing robust contingency plans, maintaining buffer inventory, and building relationships with suppliers in multiple regions. | Increased diversification of manufacturing locations, focusing on multiple regions to reduce reliance on any one region. Emphasis on more agile and responsive supply chain management systems. |

| Traditional, linear supply chain model. | Slow response to changing demand and market conditions. Difficulty in adapting to sudden shifts in consumer behavior. | Investing in data analytics to better predict demand, implementing demand forecasting tools, and building stronger relationships with retailers. | Increased focus on real-time visibility and data-driven decision-making in supply chain operations. Emphasis on agility and adaptability to respond quickly to fluctuations in demand. |

| Limited flexibility in adjusting production levels. | Difficulty in adapting production to sudden changes in demand or supply. Inability to respond rapidly to changing market conditions. | Investing in flexible manufacturing facilities and adaptable production processes to adjust to changing demands. | Developing more flexible and adaptable manufacturing processes. Employing technologies like AI and machine learning to optimize production and respond to changing demands in real time. |

Impact on HP Supply Chain

The COVID-19 pandemic significantly disrupted global supply chains, impacting various industries, including technology. HP, a major player in the tech sector, faced numerous challenges in maintaining its operations and meeting customer demands. Understanding these challenges and HP’s response provides valuable insights into navigating such crises.HP’s global supply chain, intricate and complex, relies on a vast network of suppliers, manufacturers, and logistics partners spread across the globe.

Disruptions in any part of this network could have cascading effects on production, delivery, and ultimately, customer satisfaction. The pandemic’s impact on transportation, manufacturing, and labor availability presented significant hurdles for HP.

Sourcing Component Challenges

The pandemic caused severe disruptions in the availability of critical components for HP’s products. Lockdowns, factory closures, and transportation bottlenecks led to shortages and delays in procuring essential parts. This directly impacted HP’s production capabilities, forcing them to prioritize components and adjust production schedules to minimize the impact. For example, shortages of specific semiconductors, crucial for many HP products, significantly hampered production.

Maintaining Production Schedules

Maintaining production schedules proved another significant challenge. The unpredictable nature of the pandemic and the resulting disruptions in the supply chain made it difficult to forecast demand and adjust production accordingly. HP had to implement flexible scheduling strategies to manage the fluctuations in component availability and maintain output. This included shifting production focus to alternative components and parts where possible.

Managing Logistics

Managing logistics during the pandemic was a critical concern. Shipping delays and port congestion significantly impacted delivery times for HP products. HP needed to establish alternative shipping routes, explore expedited delivery options, and collaborate with logistics providers to mitigate the delays and ensure timely delivery to customers. The ability to quickly adapt logistics strategies was vital to minimizing disruptions.

Comparison with Other Tech Companies

HP’s experience with supply chain disruptions mirrored that of other major tech companies. Many faced similar challenges in sourcing components, maintaining production, and managing logistics. However, the specific vulnerabilities and responses varied depending on the company’s supply chain structure and geographical footprint. Some companies focused on diversifying their supplier base, while others invested in robust inventory management systems.

HP’s Supply Chain Resilience Measures

To enhance its supply chain resilience, HP implemented various measures. These included diversifying its supplier base, improving inventory management, and establishing stronger relationships with key partners. The company also invested in technologies to monitor and predict potential disruptions. These proactive steps allowed HP to respond more effectively to the evolving situation.

HP Supply Chain Vulnerabilities and Mitigation Strategies

| Vulnerability | Mitigation Strategy | Impact | Result |

|---|---|---|---|

| Over-reliance on specific suppliers for critical components | Diversification of supplier base and development of alternative sourcing strategies | Production delays and potential shortages | Reduced reliance on single suppliers and improved component availability |

| Dependence on global transportation networks | Establishment of alternative shipping routes and expedited delivery options | Significant shipping delays and congestion | Faster delivery times and improved logistics flexibility |

| Lack of real-time visibility into supply chain | Implementation of advanced analytics and supply chain management tools | Difficulty in predicting and reacting to disruptions | Improved forecasting accuracy and proactive response to disruptions |

Cross-Industry Comparisons

The COVID-19 pandemic drastically reshaped global supply chains, forcing companies across various industries to adapt to unprecedented challenges. Kellogg’s, Nike, and HP, each with unique operational structures, faced similar yet distinct disruptions. Examining their responses provides valuable insights into effective strategies for navigating future crises and building more resilient supply chains.

Obtain access to association gaa support ifrs foundation sustainability reporting standards board proposal to private resources that are additional.

Supply Chain Disruption Comparisons

The pandemic’s impact on Kellogg’s, Nike, and HP’s supply chains revealed both common threads and specific vulnerabilities. All three companies experienced significant disruptions, from raw material shortages to manufacturing bottlenecks and transportation issues. These disruptions underscore the interconnectedness of global supply chains and the critical need for diversification and contingency planning.

Similarities in Approaches to Managing Disruptions

Despite their distinct industries, Kellogg’s, Nike, and HP demonstrated some common strategies in managing supply chain disruptions. All three companies prioritized communication with stakeholders, including suppliers, distributors, and customers. They also implemented strategies to enhance visibility into their supply chains, allowing for proactive identification and mitigation of potential issues. Further, all companies explored alternative sourcing strategies to reduce reliance on single suppliers and build resilience into their networks.

Differences in Approaches to Managing Disruptions

While the companies shared some strategies, differences emerged in their approaches. Kellogg’s, being a consumer goods company, focused heavily on securing alternative sources for key ingredients. Nike, with its emphasis on global manufacturing, prioritized adapting production schedules and finding alternate transportation routes. HP, heavily reliant on specialized components, invested in strengthening relationships with key suppliers and developing more agile manufacturing processes.

Industry-Wide Influence of Disruptions

The supply chain disruptions significantly influenced the industry as a whole. Companies across various sectors faced similar challenges, leading to a heightened awareness of the risks inherent in complex global supply chains. The disruptions also prompted a shift towards more localized production, diversification of sourcing, and enhanced supply chain visibility.

Discover the crucial elements that make hindustan unilever cfo srinivas phatak indian market growth the top choice.

Common Challenges and Best Practices

Several common challenges and best practices emerged across the three companies’ responses. A key challenge was the difficulty in predicting and responding to unpredictable events. Best practices included proactive communication, flexible production strategies, and building stronger relationships with suppliers.

Comparative Performance of Companies

| Company | Challenges | Response | Resilience Score (1-5, 5 being highest) |

|---|---|---|---|

| Kellogg’s | Ingredient sourcing, packaging availability, transportation delays | Diversified ingredient sourcing, expedited delivery strategies, robust inventory management | 4 |

| Nike | Manufacturing capacity constraints, transportation bottlenecks, component shortages | Adjusted production schedules, explored alternative transportation, developed agile manufacturing processes | 4.5 |

| HP | Component shortages, manufacturing delays, supply chain bottlenecks | Strengthened relationships with key suppliers, developed more agile manufacturing processes, invested in inventory management | 4 |

Note: Resilience scores are subjective and based on observed responses and available data.

Industry-Specific Implications

The global pandemic significantly disrupted supply chains across numerous industries. Analyzing the specific impacts on food, athletic footwear, and computer hardware reveals unique vulnerabilities and responses, with long-term consequences for each sector. Understanding these nuances is crucial for future resilience planning.

Food Industry Impacts

The food industry faced unprecedented challenges during the pandemic, experiencing shortages in key ingredients and difficulties in transporting finished goods. This disruption highlighted vulnerabilities in the intricate global supply networks that underpin food production and distribution. Specific impacts included delays in processing and distribution, leading to product shortages and price hikes. Farmer input supply chain challenges also created cascading effects on the entire industry.

- Ingredient Shortages: Certain key ingredients, such as spices, fruits, and vegetables, became scarce due to localized lockdowns and transportation disruptions. This affected the production of many food products, from sauces and seasonings to fresh produce and processed goods.

- Transportation Bottlenecks: Global shipping delays and port congestion hampered the movement of food products across borders. This led to significant delays in delivery and reduced product availability in markets.

- Labor Shortages: Lockdowns and health concerns resulted in labor shortages across various segments of the food industry, from farms to processing plants to distribution centers. This impacted efficiency and capacity.

Athletic Footwear Industry Impacts

The athletic footwear industry, heavily reliant on global manufacturing and supply chains, experienced significant disruptions during the pandemic. Factory closures, transportation limitations, and shifting consumer demand created substantial challenges. This highlights the vulnerability of businesses heavily dependent on international sourcing.

- Manufacturing Slowdowns: Factory closures in key Asian manufacturing hubs, along with the challenges of maintaining worker health and safety protocols, significantly reduced production capacity. This impacted the timely delivery of finished goods to retailers.

- Material Shortages: Difficulties in sourcing raw materials, such as leather and textiles, affected production schedules and product availability. This showcased the fragility of the industry’s supply network.

- Shifting Consumer Demand: The pandemic-induced shift in consumer behavior towards at-home activities affected the demand for athletic footwear. This created an imbalance between production capacity and consumer needs.

Computer Hardware Industry Impacts

The computer hardware industry, a prime example of a globalized industry, faced substantial disruptions due to pandemic-related limitations. The impact of component shortages, logistical delays, and shifts in demand was widespread. This emphasizes the vulnerability of the industry to global supply chain disruptions.

You also can investigate more thoroughly about dennis johnson cfo qlik urgency for growth to enhance your awareness in the field of dennis johnson cfo qlik urgency for growth.

- Component Shortages: A shortage of key components like semiconductors and microchips severely impacted the production of laptops, smartphones, and other electronic devices. This created a bottleneck in the entire supply chain.

- Manufacturing Delays: Factory closures and restrictions on worker movement caused production delays, impacting the delivery of finished goods to consumers. This had significant repercussions on consumer electronics sales and product availability.

- Increased Demand for Remote Work Tools: The rise in remote work and online learning increased demand for laptops and other computer hardware, exacerbating the shortage issues.

Industry-Specific Response and Long-Term Implications

Companies within these industries adopted various strategies to mitigate the impact of supply chain disruptions. This included diversifying their supply sources, establishing closer relationships with suppliers, and improving inventory management. These responses highlighted the need for greater resilience in global supply chains. Long-term implications included a greater focus on local sourcing and regionalization of production to reduce reliance on distant suppliers.

| Industry | Vulnerability | Mitigation Strategies | Long-Term Implications |

|---|---|---|---|

| Food | Dependence on global supply chains, ingredient shortages, transportation bottlenecks, labor shortages | Diversification of sourcing, enhanced inventory management, investment in local production, improved logistics | Increased emphasis on local food production, greater resilience to global disruptions, potential for increased food prices in some cases |

| Athletic Footwear | Heavy reliance on international manufacturing, material shortages, shifting consumer demand | Diversification of manufacturing locations, strengthening supplier relationships, investment in alternative materials, adaptation to changing demand | Potential for regionalization of production, increased focus on sustainability in sourcing, greater resilience to disruptions in global supply chains |

| Computer Hardware | Dependence on global component supply, manufacturing delays, shifting demand | Diversification of component sourcing, investment in domestic manufacturing capacity, improved inventory management, supply chain visibility | Greater emphasis on domestic manufacturing, potential for increased prices, stronger focus on supply chain resilience |

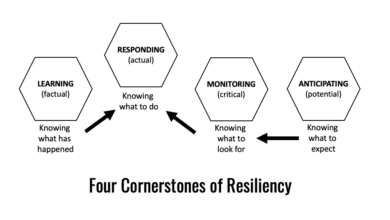

Future Supply Chain Resilience

The recent global disruptions, exemplified by the coronavirus pandemic’s impact on Kellogg’s, Nike, and HP, have underscored the critical need for robust and adaptable supply chains. Companies must proactively prepare for future shocks, recognizing that relying on a single source or a geographically concentrated network leaves them vulnerable. Building resilience is not a one-time project but an ongoing commitment to continuous improvement.The ability to navigate future disruptions depends on a proactive approach, embracing strategies that foster flexibility, adaptability, and diversification.

This involves more than just reacting to events; it requires anticipating potential risks and building safeguards into the core operational structure. By prioritizing diversification, redundancy, and meticulous risk assessment, companies can significantly enhance their resilience and maintain business continuity.

Diversification Strategies

Diversifying supply sources is crucial for mitigating risks associated with single points of failure. Instead of relying heavily on a single supplier, companies should explore alternative sources of raw materials, components, and finished goods. This can involve geographically dispersed sourcing strategies, which reduces reliance on a single region or country. For example, a clothing manufacturer like Nike can establish relationships with suppliers across multiple continents to reduce vulnerability to local disruptions.

Redundancy and Backup Plans

Redundancy in supply chain infrastructure provides critical backup capabilities. This involves having multiple suppliers, alternative transportation routes, and backup facilities. For instance, having multiple warehousing locations allows for flexibility and quicker response times in the event of a disruption, ensuring product availability to meet demand.

Risk Assessment and Mitigation

A thorough risk assessment is the foundation for effective supply chain resilience. This involves identifying potential disruptions, such as natural disasters, geopolitical instability, or pandemics, and evaluating their potential impact. The assessment should quantify the potential consequences and determine the likelihood of each risk occurring. For instance, a company like Kellogg’s could use historical data to assess the impact of a drought on agricultural production in specific regions.

Technology and Data Analytics

Technology and data analytics play a pivotal role in strengthening supply chains. Real-time tracking of inventory levels, predictive analytics for demand forecasting, and improved communication channels between suppliers and retailers significantly enhance visibility and responsiveness. For example, HP can use data analytics to predict potential component shortages and proactively adjust production schedules.

Collaboration Among Stakeholders

Collaboration between suppliers, manufacturers, distributors, and retailers is essential for navigating disruptions. Building strong relationships based on trust and open communication fosters a network capable of adapting to unexpected events. Companies can achieve this by developing joint contingency plans and sharing information about potential risks. A good example is a collaborative approach between a manufacturer like Kellogg’s and its agricultural suppliers to ensure a steady flow of ingredients during a drought.

Framework for Proactive Preparation

“Proactive supply chain resilience isn’t just about reacting; it’s about anticipating and preventing disruptions.”

- Identify Potential Disruptions: Thorough analysis of historical data, geopolitical trends, and industry reports to identify potential vulnerabilities.

- Develop Contingency Plans: Create specific plans for various disruptions, outlining alternative sourcing strategies, transportation routes, and production schedules.

- Diversify Supply Sources: Explore multiple suppliers and locations to reduce reliance on single points of failure.

- Enhance Data Visibility: Utilize technology and data analytics to track inventory, predict demand, and monitor supplier performance.

- Strengthen Stakeholder Relationships: Foster strong communication and collaboration with suppliers, distributors, and retailers to facilitate information sharing and joint planning.

Last Recap

The coronavirus pandemic exposed critical vulnerabilities in global supply chains, forcing companies like Kellogg’s, Nike, and HP to adapt quickly. Their responses, while unique, offered valuable insights into resilience strategies. This analysis underscores the importance of diversification, redundancy, and proactive risk assessment. The future of supply chain management hinges on leveraging technology, data analytics, and collaboration among stakeholders to build more robust and adaptable systems.