Supply Chain Management Coronavirus Pandemic Lessons

Supply chain management coronavirus pandemic lessons offer crucial insights into navigating future disruptions. The global pandemic exposed vulnerabilities in existing systems, prompting a surge in resilience strategies and technological advancements. From border closures to labor shortages, the pandemic drastically altered the landscape of global commerce, forcing businesses to adapt and innovate.

This exploration delves into the specific ways supply chains were impacted, examining disruptions across various industries and regions. We’ll analyze the strategies businesses employed to become more resilient, focusing on diversification, alternative suppliers, real-time data, and innovative solutions. Furthermore, the importance of technological advancements, visibility, transparency, collaboration, risk management, and mitigation strategies will be examined in detail. Lessons learned from this period will equip us to build more robust and adaptable supply chains for the future.

Supply Chain Disruptions

The COVID-19 pandemic profoundly reshaped global supply chains, exposing vulnerabilities and triggering unprecedented disruptions across industries. From factory closures to port congestion, the ripple effects of the pandemic continue to impact businesses and consumers worldwide. Understanding the specific disruptions, their impacts, and the varying responses across regions is crucial for building more resilient supply chains in the future.

Impact of Border Closures and Lockdowns

Border closures and lockdowns implemented to control the spread of the virus significantly hampered the flow of goods. Restrictions on movement of people and products led to delays in shipments, impacting manufacturing, distribution, and retail. For example, many countries experienced substantial delays in importing raw materials and exporting finished goods. This disruption was particularly acute in industries reliant on international trade, such as automotive, electronics, and apparel.

Manufacturing plants in countries with strict lockdowns were forced to halt operations, leading to shortages of critical components and finished products. The inability to move goods across borders caused shortages of essential supplies like medical equipment and pharmaceuticals in some regions.

Product Shortages Caused by Supply Chain Disruptions

The pandemic exposed vulnerabilities in supply chains, leading to shortages of various products. The disruption of global production and transportation networks created bottlenecks that impacted the availability of goods. For example, there were widespread shortages of personal protective equipment (PPE) such as masks and gloves in the early stages of the pandemic. Similarly, shortages of semiconductors, crucial components in electronics, impacted the production of automobiles and consumer electronics.

These shortages had a cascade effect, affecting various downstream industries and consumers.

Role of Labor Shortages in Supply Chain Disruptions, Supply chain management coronavirus pandemic lessons

Labor shortages played a significant role in supply chain disruptions. Lockdowns and health concerns led to worker absenteeism and reduced workforce availability in many sectors, including transportation, warehousing, and manufacturing. This labor scarcity exacerbated existing bottlenecks and created new challenges in meeting demand. For example, truck driver shortages led to delays in transporting goods, while worker shortages in warehouses hampered the efficient processing and distribution of products.

The ripple effect of these shortages was felt throughout the supply chain.

Impact of Increased Demand on Specific Supply Chain Links

Increased demand for certain products during the pandemic further stressed specific supply chain links. The shift in consumer behavior toward online shopping, coupled with increased demand for essential goods, placed immense pressure on logistics providers, warehouses, and delivery services. For example, e-commerce fulfillment centers faced significant challenges in handling the surge in orders, resulting in delays and potential shortages of goods.

Comparison and Contrast of Disruption Levels Across Regions

The impact of supply chain disruptions varied across different regions. Factors such as the severity of the pandemic, the effectiveness of government responses, and the resilience of local supply chains influenced the extent of disruptions. Some regions experienced more severe disruptions than others due to the differing levels of lockdown measures and the degree of dependence on international trade.

Investigate the pros of accepting how to clearly communicate feedback and expectations in your business strategies.

For instance, regions heavily reliant on imported components faced more pronounced shortages than those with more diversified supply sources.

Supply Chain Disruption Summary Table

| Industry | Product | Region | Cause |

|---|---|---|---|

| Automotive | Semiconductors | North America | Factory closures in Asia |

| Electronics | Consumer electronics | Europe | Port congestion in major shipping hubs |

| Pharmaceuticals | Medical supplies | Developing countries | Limited production capacity and transportation bottlenecks |

| Retail | Clothing | Asia | Labor shortages in manufacturing and logistics |

Resilience and Adaptability

The COVID-19 pandemic exposed vulnerabilities in global supply chains, highlighting the need for greater resilience and adaptability. Businesses that successfully navigated the disruptions did so by proactively enhancing their supply chain strategies, embracing diversification, and adopting innovative solutions. This resilience was not just about reacting to immediate crises; it was about building a future-proof supply chain capable of withstanding future shocks.Businesses responded to the pandemic’s challenges by implementing various strategies aimed at enhancing supply chain resilience.

Discover how cima ethics confidentiality rules has transformed methods in this topic.

These approaches included a reassessment of their supply base, exploring alternative logistics providers, and investing in real-time data analytics to better anticipate and respond to potential disruptions. The key was to move beyond simply reacting to problems and instead proactively build a supply chain capable of adapting to a dynamic global environment.

Strategies for Enhancing Supply Chain Resilience

Businesses employed various strategies to bolster their supply chain resilience. Diversification of suppliers and geographic locations proved crucial. Companies also shifted towards alternative transportation modes and logistics partners. Real-time data and analytics played a critical role in anticipating and mitigating disruptions.

Diversification in Supply Chains

Diversifying supply chains is a vital component of resilience. By relying on multiple suppliers and sources, companies reduce their vulnerability to disruptions at a single point. This approach ensures business continuity in case of unforeseen circumstances impacting a particular supplier. For example, a company that sources raw materials from a single region might face significant issues if that region experiences a natural disaster.

Diversifying its supply sources across multiple regions significantly mitigates this risk.

Shifting to Alternative Suppliers and Logistics Partners

The pandemic prompted many businesses to explore and adopt alternative suppliers and logistics partners. This strategy, often a combination of careful pre-planning and quick responses, enabled companies to maintain operations and meet customer demand. For instance, a company reliant on a single ocean freight carrier might switch to a different carrier or explore air freight as an alternative if the primary carrier faces capacity issues.

Importance of Real-Time Data in Supply Chain Management

Real-time data and analytics are critical for proactive supply chain management. By monitoring inventory levels, tracking shipments, and analyzing demand patterns, companies can anticipate potential disruptions and adjust their strategies in advance. For instance, real-time data on shipping delays allows companies to adjust their production schedules and order quantities, preventing potential shortages.

Innovative Solutions for Improved Supply Chain Responsiveness

Several innovative solutions emerged to improve supply chain responsiveness. These include implementing advanced forecasting models, using blockchain technology for transparency and traceability, and developing more agile production processes. Cloud-based platforms enabling remote collaboration and real-time data sharing also played a crucial role.

Comparison of Resilience Strategies Adopted by Different Companies

Different companies adopted varying resilience strategies, often tailored to their specific industry and supply chain characteristics. Some prioritized diversification of suppliers, while others focused on developing closer relationships with key partners. The strategies were often a mix of proactive planning and agile responses to specific disruptions.

Top 3 Resilience Strategies Adopted by Different Sectors

| Sector | Top 3 Resilience Strategies |

|---|---|

| Consumer Electronics | 1. Diversification of component suppliers 2. Development of alternative manufacturing locations 3. Enhanced inventory management |

| Automotive | 1. Increased collaboration with key suppliers 2. Agile production scheduling and inventory management 3. Development of resilient logistics networks |

| Pharmaceuticals | 1. Strategic partnerships with multiple manufacturers and distributors 2. Building buffer inventory of essential raw materials 3. Investing in robust supply chain visibility tools |

Technological Advancements: Supply Chain Management Coronavirus Pandemic Lessons

The COVID-19 pandemic acted as a catalyst for rapid technological advancements across various sectors, including supply chains. Businesses accelerated their adoption of digital tools and technologies to enhance resilience, efficiency, and visibility. This period saw a significant shift towards automation, data-driven decision-making, and enhanced transparency, all aimed at mitigating disruptions and optimizing operations.The pandemic highlighted the vulnerability of traditional supply chains and the need for greater adaptability.

This realization spurred a surge in the implementation of technologies like artificial intelligence (AI), machine learning, and automation to improve forecasting, optimize logistics, and enhance overall supply chain performance. These innovations became critical to maintaining operational continuity and responding to unforeseen challenges.

AI and Machine Learning for Forecasting and Optimization

AI and machine learning algorithms have proven invaluable in improving supply chain forecasting and optimization. These technologies can analyze vast amounts of data from various sources, including historical sales data, market trends, and external factors, to predict future demand with greater accuracy. This allows businesses to adjust inventory levels, optimize production schedules, and allocate resources more effectively. For example, retailers can use AI to predict seasonal fluctuations in demand, ensuring they have the right products in stock at the right time.

Supply Chain Automation Tools

Automation has played a crucial role in streamlining supply chain processes. This includes the implementation of robotic process automation (RPA) tools for tasks such as order processing, invoice reconciliation, and data entry. Furthermore, warehouse automation, with the use of automated guided vehicles (AGVs) and automated storage and retrieval systems (AS/RS), has significantly improved efficiency and reduced errors in warehousing and distribution.

These advancements reduce labor costs and minimize potential human error.

Data Analytics for Improved Decision-Making

Data analytics has become integral to informed decision-making in supply chains. By collecting and analyzing data from various sources, businesses can gain a comprehensive understanding of their supply chain performance. This includes insights into inventory levels, delivery times, and customer demand. Using this data, businesses can identify bottlenecks, optimize processes, and proactively address potential disruptions. Real-time dashboards and reporting tools provide crucial insights into supply chain performance, enabling faster responses to changing conditions.

Digitalization for Supply Chain Visibility and Transparency

Digitalization has fostered enhanced visibility and transparency throughout the supply chain. This is facilitated by the use of cloud-based platforms and interconnected systems, allowing real-time tracking of goods and information sharing between different stakeholders. This transparency builds trust and allows for more efficient collaboration and problem-solving across the entire supply chain network. The implementation of blockchain technology is further improving transparency by providing a secure and immutable record of transactions.

Effectiveness of Different Technological Solutions

The effectiveness of different technological solutions varies depending on the specific needs and context of each supply chain. While AI and machine learning excel at predictive modeling and optimization, automation tools are particularly valuable for streamlining repetitive tasks. Data analytics provides crucial insights for decision-making, while digitalization enhances visibility and collaboration. A successful implementation requires careful consideration of the specific challenges and opportunities within each supply chain.

Comparative Analysis of Technological Advancements

| Technology | Application | Benefits |

|---|---|---|

| AI & Machine Learning | Demand forecasting, inventory optimization, predictive maintenance | Improved accuracy, reduced costs, enhanced responsiveness |

| Automation (RPA, AGVs, AS/RS) | Order processing, warehouse operations, logistics | Increased efficiency, reduced errors, faster processing times |

| Data Analytics | Performance monitoring, identifying bottlenecks, risk assessment | Improved decision-making, proactive risk management, optimized resource allocation |

| Digitalization (Cloud, Blockchain) | Supply chain visibility, transparency, collaboration | Enhanced communication, improved stakeholder trust, reduced lead times |

Supply Chain Visibility and Transparency

The COVID-19 pandemic exposed vulnerabilities in global supply chains, highlighting the critical need for improved visibility and transparency. Companies that lacked real-time insights into their supply networks struggled to adapt to disruptions, leading to shortages, delays, and increased costs. This realization spurred a significant shift towards strategies that enhanced visibility and transparency throughout the entire supply chain.Understanding the intricacies of supply chains is paramount for proactive management.

Without clear visibility into inventory levels, production capacities, and potential bottlenecks, companies are susceptible to unforeseen events. The pandemic acted as a catalyst, forcing organizations to prioritize building more resilient and adaptable supply chains. Increased transparency and visibility are key components of this transformation.

Importance of Visibility and Transparency

Effective visibility and transparency empower businesses to anticipate and react swiftly to disruptions. This proactive approach minimizes risks and ensures uninterrupted operations. Detailed insights into each stage of the supply chain, from raw material sourcing to final delivery, enable informed decision-making. Real-time data on inventory levels, transportation status, and production schedules facilitates dynamic adjustments to changing market conditions.

Furthermore, transparency fosters trust and collaboration among stakeholders, enhancing overall supply chain performance.

How the Pandemic Highlighted the Need for Greater Transparency

The pandemic’s disruption exposed the lack of transparency in many supply chains. Sudden shutdowns in manufacturing hubs, port congestion, and logistical bottlenecks revealed the vulnerability of relying on opaque networks. Companies struggling with a lack of visibility had limited ability to adjust their strategies, leading to significant delays and increased costs. The need for real-time data and collaborative information sharing became apparent.

The pandemic acted as a wake-up call, driving companies to invest in systems and processes that could provide a clear view of their supply chain operations.

Use of Blockchain Technology in Improving Supply Chain Transparency

Blockchain technology offers a decentralized and secure way to record and share information throughout the supply chain. By creating a transparent, immutable ledger of transactions, blockchain enables stakeholders to verify the authenticity of products, track their movement, and monitor their origin. This transparency reduces fraud, improves traceability, and fosters trust among partners. For instance, a food company can use blockchain to track the journey of its produce from farm to consumer, verifying that it meets specific quality and safety standards.

Role of Real-Time Tracking Systems in Maintaining Visibility

Real-time tracking systems provide continuous updates on the location and status of goods in transit. These systems offer detailed insights into transportation schedules, potential delays, and any disruptions that might impact delivery times. GPS tracking, RFID tags, and other technologies allow for continuous monitoring, facilitating timely adjustments and proactive risk mitigation. For example, a logistics company can use real-time tracking to reroute shipments avoiding congestion, ensuring timely delivery.

Importance of Data Sharing Among Stakeholders

Sharing data among stakeholders is critical for maintaining supply chain visibility. This collaborative approach enables stakeholders to gain a holistic view of the supply chain, anticipate potential disruptions, and work together to mitigate risks. By sharing real-time data, stakeholders can coordinate efforts, streamline processes, and optimize resource allocation. For instance, manufacturers can share production schedules with distributors, enabling better inventory management and avoiding stockouts.

How Improved Visibility Reduced Uncertainty and Risks

Improved visibility reduces uncertainty and risks by providing a clear understanding of the entire supply chain. This clarity allows for proactive risk management, enabling companies to anticipate potential disruptions and develop contingency plans. By understanding the flow of goods and materials, companies can identify potential bottlenecks and address them before they impact operations. For example, knowing the location and status of raw materials enables companies to adjust production schedules to minimize delays.

Comparison of Visibility and Transparency Solutions

| Solution | Description | Advantages | Disadvantages |

|---|---|---|---|

| Real-time tracking systems | Provides continuous updates on goods in transit | Improved delivery time accuracy, proactive disruption management | Requires investment in technology and infrastructure |

| Blockchain technology | Creates a secure and transparent ledger of transactions | Enhanced traceability, reduced fraud, increased trust | Requires integration across all stakeholders |

| Data sharing platforms | Enables collaboration and information sharing among stakeholders | Improved coordination, proactive risk management | Requires trust and standardization of data formats |

Collaboration and Partnerships

The COVID-19 pandemic dramatically highlighted the critical role of collaboration in navigating complex supply chain disruptions. Businesses, governments, and international organizations realized the limitations of operating in silos and the necessity of shared resources and knowledge to overcome challenges. This newfound understanding fostered innovative partnerships and collaborative initiatives, which significantly impacted supply chain resilience and adaptability.Effective collaboration is essential for building supply chain resilience.

By sharing resources, expertise, and information, businesses can anticipate and respond more effectively to future disruptions. This collective approach allows for faster problem-solving, improved resource allocation, and ultimately, a more robust and adaptable supply chain network. The pandemic served as a catalyst for this shift in perspective, demonstrating that working together is not just beneficial but often necessary for survival.

Importance of Collaboration Among Businesses and Stakeholders

Collaboration among businesses, suppliers, and logistics providers is crucial for efficient and resilient supply chains. Sharing information about potential disruptions, coordinating production schedules, and developing contingency plans are vital steps. This collective effort can help minimize the impact of unforeseen events and ensure continued operations. For example, manufacturers can collaborate with their suppliers to diversify their sourcing strategies, reducing reliance on single points of failure.

Impact of Government Support on Supply Chain Resilience

Government support plays a pivotal role in fostering supply chain resilience. Financial incentives, regulatory adjustments, and infrastructure investments can stimulate innovation and adaptation. For example, grants and subsidies for companies investing in automation or diversification can accelerate the adoption of new technologies and strategies. Moreover, streamlined import/export procedures can facilitate the movement of goods and services, thus reducing bottlenecks and delays.

Examples of Successful Partnerships Forged During the Pandemic

Several successful partnerships emerged during the pandemic. One notable example involves pharmaceutical companies collaborating with logistics providers to expedite the delivery of vaccines. This collaboration streamlined the distribution process, enabling rapid vaccine deployment across the globe. Similarly, retailers partnered with technology companies to implement real-time tracking systems for their products, improving visibility and responsiveness to disruptions.

You also will receive the benefits of visiting positive outlook financial services work in europe today.

Role of International Cooperation in Addressing Supply Chain Issues

International cooperation is vital for addressing global supply chain issues. Sharing best practices, coordinating responses to disruptions, and establishing common standards can significantly improve overall resilience. This collective approach enables nations to pool resources, knowledge, and expertise to navigate shared challenges. For example, joint research efforts on new technologies for supply chain management can lead to innovations applicable globally.

Examples of Collaborative Initiatives to Improve Logistics

Several collaborative initiatives emerged to improve logistics during the pandemic. One example involves logistics providers partnering with technology companies to develop advanced tracking and monitoring systems. These systems provide real-time visibility into shipments, enabling faster identification and resolution of potential problems. Similarly, businesses are collaborating to share warehousing space, optimizing inventory management and minimizing storage costs.

Benefits of Supply Chain Partnerships

Supply chain partnerships offer numerous benefits, including increased efficiency, reduced costs, and enhanced resilience. Collaboration can lead to better inventory management, streamlined logistics, and improved communication among stakeholders. These partnerships also foster innovation, leading to the development of new technologies and strategies to improve supply chain performance.

Table of Collaborative Projects Between Different Companies

| Company A | Company B | Project Description |

|---|---|---|

| XYZ Pharmaceuticals | ABC Logistics | Developed a streamlined vaccine delivery network, using real-time tracking and optimized routes to ensure timely vaccine distribution across the country. |

| Retail Giant Corp | Tech Solutions Inc | Implemented a real-time tracking system for inventory, providing visibility into the movement of goods throughout the supply chain, which enabled the company to respond effectively to unexpected demand changes and disruptions. |

| Auto Parts Inc | Supplier Network Consortium | Established a collaborative platform for sharing information on potential disruptions and coordinating production schedules to minimize the impact of supply chain disruptions on their manufacturing processes. |

Risk Management and Mitigation

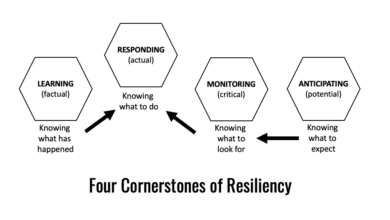

The COVID-19 pandemic highlighted the critical importance of proactive risk management in supply chains. Companies that had robust risk management frameworks in place were better positioned to navigate the unprecedented disruptions, minimizing damage and ensuring business continuity. A well-defined risk management strategy is no longer a desirable add-on but a fundamental necessity for sustainable operations in today’s volatile environment.Effective risk management isn’t just about reacting to crises; it’s about anticipating potential issues, assessing their likelihood and impact, and implementing strategies to mitigate them.

This proactive approach allows businesses to maintain operational resilience and adapt to changing circumstances more effectively.

Identification of Potential Risks and Vulnerabilities

A comprehensive risk assessment involves identifying potential disruptions across all stages of the supply chain. This includes evaluating risks related to geopolitical instability, natural disasters, pandemics, economic downturns, and even supplier failures. Analyzing historical data, industry trends, and expert opinions are critical to understanding the likelihood and potential impact of these risks. Furthermore, understanding the specific vulnerabilities within your supply chain, such as single sourcing dependencies or geographical concentration, is vital for targeted risk mitigation.

Companies must also consider the cascading effects of risks, recognizing how a disruption in one part of the chain can impact other areas.

Implementation of Contingency Plans for Disruptions

Having contingency plans in place is crucial for responding effectively to supply chain disruptions. These plans should Artikel specific actions to be taken in the event of various risks, from a sudden surge in demand to a prolonged shortage of raw materials. They should detail alternative suppliers, transportation routes, and production facilities. The plans must be regularly reviewed and updated to ensure their continued relevance and effectiveness.

A key component is clear communication protocols among stakeholders, enabling swift decision-making and coordination during crises.

Examples of Proactive Risk Mitigation Strategies

Diversifying suppliers is a crucial risk mitigation strategy. Relying on a single supplier exposes a business to significant risk. Expanding the supplier base to include multiple sources in different geographic locations reduces dependence on any one entity. Similarly, building strategic partnerships with suppliers can provide access to critical resources and expertise, enabling a more resilient supply chain.

Maintaining buffer stock levels is another proactive measure, allowing companies to absorb unexpected demand surges or supply disruptions.

Lessons Learned about Supply Chain Risk Assessment

The pandemic highlighted the inadequacy of traditional risk assessments, which often focused on well-defined events and underestimated the potential impact of unexpected disruptions. A significant lesson learned is the importance of incorporating scenario planning and analyzing the potential ripple effects of various events. Furthermore, companies learned the importance of understanding their suppliers’ supply chains, allowing for more accurate forecasting and risk mitigation.

Comparison and Contrast of Different Risk Management Methodologies

Different methodologies exist for supply chain risk management. The Delphi method, for instance, utilizes expert opinions to assess risks, while Monte Carlo simulations model the impact of various scenarios. Fault tree analysis helps identify the root causes of potential failures. Each method has its strengths and weaknesses, and the optimal choice depends on the specific context and resources available.

Careful consideration of factors such as data availability and expertise required is critical for selecting the most suitable methodology.

Structured Risk Management Approach

| Risk Category | Potential Risk | Likelihood | Impact | Mitigation Strategy |

|---|---|---|---|---|

| Geopolitical Instability | Trade restrictions | Medium | High | Diversify suppliers, develop contingency plans for border closures |

| Natural Disasters | Flooding | Low | High | Establish alternative logistics routes, maintain backup storage facilities |

| Supply Shortages | Raw material scarcity | Medium | Medium | Develop alternative material sources, increase inventory levels |

This table provides a structured framework for identifying and mitigating risks. It’s crucial to remember that this is a dynamic process, requiring ongoing review and adaptation. Regular updates and adjustments to the table are essential to maintain relevance.

Closing Notes

In conclusion, the coronavirus pandemic acted as a crucible for supply chains, forcing businesses to confront vulnerabilities and adapt rapidly. The lessons learned extend far beyond the immediate crisis, emphasizing the need for resilience, adaptability, and a proactive approach to risk management. From diversification to technological advancements, collaboration to risk mitigation, businesses that embraced these principles emerged stronger and better equipped to face future challenges.

The future of supply chain management lies in learning from these experiences and proactively building more sustainable, transparent, and responsive systems.