Managing Warehousing Post-Disruption Brexit & COVID

Managing warehousing after supply chain disruption coronavirus brexit – Managing warehousing after supply chain disruption, coronavirus, and Brexit, requires a comprehensive approach. The pandemic and the UK’s departure from the EU dramatically reshaped global supply chains, impacting everything from e-commerce fulfillment to manufacturing logistics. This necessitates a deep dive into adapting warehousing operations, including inventory strategies, workforce management, technology integration, supply chain visibility, and crucial safety protocols.

We’ll explore the specific challenges and effective solutions to build resilient warehousing operations.

This post will detail the key impacts of these disruptions on various warehousing sectors, exploring innovative inventory management strategies, and the critical role of technology in fostering resilience. We’ll also delve into workforce adaptation, highlighting the importance of automation, training, and attracting new talent. Finally, the post will examine the critical aspects of supply chain visibility, collaboration, and enhanced safety protocols for a secure and efficient warehousing ecosystem.

Impact of Disruptions on Warehousing

The COVID-19 pandemic and Brexit significantly reshaped global supply chains, creating unprecedented challenges for warehousing operations. These disruptions forced warehouses to adapt rapidly to changing customer demands, labor market shifts, and supply chain bottlenecks. Understanding the specific impacts and successful adaptation strategies is crucial for future resilience in the face of similar crises.

Impact Summary of COVID-19 and Brexit

The COVID-19 pandemic triggered widespread lockdowns, leading to labor shortages, disrupted transportation networks, and surges in demand for essential goods. Brexit, with its associated trade barriers and customs procedures, further complicated supply chains. Warehouses, positioned at the nexus of these disruptions, struggled to maintain efficient operations. They faced unprecedented challenges in adapting to the new reality, ranging from workforce management to inventory forecasting.

Challenges Faced by Warehouses

Warehouses faced numerous challenges during these disruptions. Labor shortages were a major issue, as workers were infected, quarantined, or sought employment elsewhere. Supply chain bottlenecks, particularly in transportation and logistics, resulted in delays and increased costs. Furthermore, fluctuating customer demand patterns, driven by the shift to e-commerce and changes in consumer behavior, created unpredictable workloads and inventory management issues.

Impact on Different Warehousing Types

The impact of these disruptions varied across different types of warehousing facilities. E-commerce warehouses, for example, experienced a dramatic increase in order volume and need for faster fulfillment. Manufacturing warehouses faced challenges in maintaining consistent supply lines and responding to fluctuating production schedules. Third-party logistics (3PL) warehouses, acting as intermediaries, were forced to navigate complex international trade regulations and manage multiple clients’ inventory needs.

Refrigerated and temperature-controlled warehouses, crucial for perishable goods, had to adapt to maintain optimal storage conditions during the disruptions.

Successful Adaptation Strategies

Warehouses that successfully navigated these disruptions implemented several adaptation strategies. These included investing in automation technologies, such as robotic picking systems, to mitigate labor shortages. Efficient inventory management systems, capable of forecasting demand and optimizing stock levels, were critical. Stronger relationships with reliable transportation providers and strategic partnerships with suppliers were also key to maintaining smooth supply chains.

Finally, proactive communication with customers regarding potential delays and adapting to evolving customer demands were essential.

Comparison of Impacts on Warehousing Sectors

| Warehousing Sector | Impact of COVID-19 | Impact of Brexit |

|---|---|---|

| E-commerce | Increased order volume, need for faster fulfillment, surge in demand for certain goods, and labor shortages | Increased complexity in cross-border trade, potential for delays and customs issues, adjustments to import/export procedures |

| Manufacturing | Disrupted supply chains, fluctuating production schedules, and labor shortages | Increased trade costs, new customs requirements, and adjustments to supply chain routes |

| 3PL | Increased pressure to manage multiple clients’ inventories and navigate complex disruptions, potential delays in delivery, and need for flexible operations | Increased complexity in managing cross-border trade, complying with new regulations, and adjusting to trade barriers |

| Refrigerated/Temperature-Controlled | Maintaining optimal storage conditions during disruptions and ensuring the integrity of perishable goods | Increased scrutiny of import/export procedures and potential delays in transportation |

Inventory Management Strategies

Navigating the unpredictable waters of post-disruption supply chains demands a robust and adaptable inventory management strategy. Traditional methods, often built on predictable patterns, are no longer sufficient. Companies must now embrace dynamic approaches that account for volatility and optimize resources in the face of ongoing uncertainty. This requires a shift from reactive measures to proactive strategies that minimize risk and maximize efficiency.Inventory levels, a crucial aspect of any warehousing operation, must be carefully balanced.

Overstocking ties up capital and risks obsolescence, while understocking can lead to lost sales and dissatisfied customers. A well-defined inventory management system, incorporating modern forecasting techniques and real-time data, is critical for success in this new environment.

Optimizing Inventory Levels in Uncertain Times

Successfully managing inventory in a post-disruption world requires a flexible and responsive approach. This means continuously monitoring demand fluctuations, supplier lead times, and potential disruptions, adjusting inventory levels accordingly. Companies should aim for an optimal balance between maintaining sufficient stock to meet customer demand and minimizing the risks associated with excess inventory.

Inventory Management Models

Different inventory management models offer varying degrees of effectiveness in a post-disruption environment. The Just-in-Time (JIT) model, while efficient in stable times, can be highly vulnerable to supply chain hiccups. In contrast, a more robust approach might involve maintaining safety stock levels to mitigate the impact of delays.ABC analysis, a method for categorizing inventory items by their value and importance, remains relevant.

High-value items (A) often necessitate more stringent control measures to avoid stockouts. Medium-value (B) and low-value (C) items can be managed with less stringent controls, while still accounting for potential disruptions. A hybrid approach, blending JIT with safety stock strategies, may be ideal for maximizing efficiency while mitigating risk.

Evolving Forecasting Methods

Traditional forecasting methods often struggle to predict demand in a world characterized by supply chain volatility. Modern forecasting models need to incorporate more variables, such as supplier reliability, geopolitical events, and even pandemic-related disruptions. Machine learning algorithms and statistical models are increasingly used to analyze complex datasets and generate more accurate and adaptive forecasts. For example, companies can leverage data from previous disruptions, like the COVID-19 pandemic, to build more robust models for future predictions.

Real-Time Data in Inventory Management

Real-time data is paramount for successful inventory management in a dynamic environment. Access to up-to-the-minute information on stock levels, supplier lead times, and demand patterns enables proactive adjustments to inventory strategies. This responsiveness is vital for mitigating the impact of disruptions and ensuring uninterrupted operations. Systems that integrate with various supply chain partners and offer real-time visibility are essential.

Inventory Management Software Solutions

Choosing the right inventory management software is critical for optimizing warehouse operations. Different solutions offer varying functionalities and levels of support for various needs. Consider factors such as scalability, ease of use, integration capabilities, and cost when selecting a software solution.

| Software Solution | Benefits | Drawbacks |

|---|---|---|

| Software A | Excellent real-time tracking, seamless integration with ERP systems | Steep learning curve, high initial investment |

| Software B | User-friendly interface, affordable pricing | Limited customization options, potential integration issues |

| Software C | Robust reporting features, detailed analytics | Complex setup process, potentially slower response time |

Labor Force and Workforce Management

The COVID-19 pandemic and Brexit significantly impacted global supply chains, leading to unprecedented shifts in warehousing operations. These disruptions exposed vulnerabilities in existing labor models and highlighted the critical need for adaptable and resilient workforce strategies. Warehousing companies now face a new reality demanding proactive approaches to workforce management, automation integration, and employee engagement.Warehousing operations require a workforce that is not only physically capable but also digitally adept and adaptable to changing technological landscapes.

A focus on training and upskilling is essential to equip employees with the necessary tools for success in the modern warehouse. This requires a holistic approach, moving beyond basic tasks to encompass a broader range of responsibilities, such as data analysis, equipment operation, and process optimization.

Workforce Changes Needed in Warehousing

The post-disruption warehousing landscape necessitates a more agile and tech-savvy workforce. This includes a greater emphasis on employees with experience in using warehouse management systems (WMS), picking, packing, and loading/unloading procedures. There’s also a need for individuals with data analysis skills to monitor inventory levels, identify trends, and improve operational efficiency. Beyond core skills, soft skills like teamwork, communication, and problem-solving are crucial for success in a complex and dynamic environment.

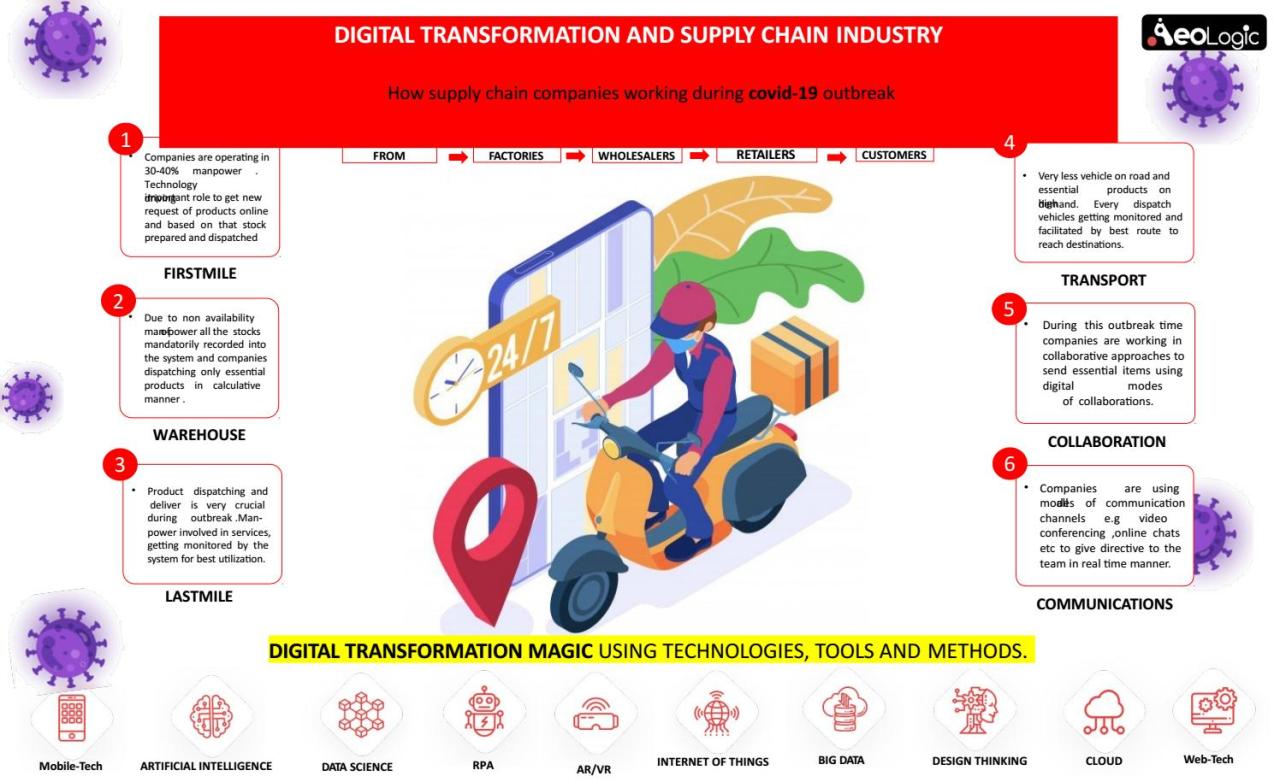

Automation and Technology in Warehousing

Automation plays a critical role in mitigating labor shortages and improving efficiency. Automated guided vehicles (AGVs), robotic process automation (RPA), and machine learning (ML) algorithms can automate tasks such as material handling, order fulfillment, and inventory management. These technologies free up human workers to focus on higher-value tasks, increasing overall productivity and reducing operational costs. The integration of these technologies should be strategic and phased, ensuring that the transition is manageable and minimizes disruption.

Innovative Approaches to Attracting and Retaining Warehouse Workers

Innovative approaches to attracting and retaining warehouse workers are essential for long-term success. Companies can consider competitive compensation packages, including benefits and incentives. Offering opportunities for career advancement and skill development is crucial. Creating a positive and supportive work environment, fostering a sense of community among employees, and promoting a healthy work-life balance are also vital. Providing opportunities for employees to contribute to the company’s goals and have a sense of ownership is critical to engagement and retention.

Examples of Innovative Approaches

One example of an innovative approach is offering tuition reimbursement for employees pursuing relevant certifications or degrees in logistics or supply chain management. Another is implementing flexible scheduling options that allow employees to better manage their work-life balance. Companies could also provide on-site childcare facilities or transportation assistance to ease the burden on employees. Mentorship programs that pair experienced workers with new hires can provide invaluable guidance and support.

Obtain access to positive outlook financial services work in europe to private resources that are additional.

Training Programs for Warehouse Staff, Managing warehousing after supply chain disruption coronavirus brexit

Comprehensive training programs are essential to adapt warehouse staff to new processes and technologies. These programs should include modules on WMS usage, robotics operation, data analysis, and problem-solving. Training should be ongoing, with regular updates and refresher courses to keep employees current with evolving technologies. This ensures that employees are well-equipped to handle new challenges and contribute to operational efficiency.

The training programs should be tailored to the specific needs of the warehouse and the skills required for each role.

Comparison of Automation Solutions

| Automation Solution | Description | Pros | Cons | Cost |

|---|---|---|---|---|

| Automated Guided Vehicles (AGVs) | Self-driving vehicles that transport materials within a warehouse. | Increased efficiency, reduced labor costs, improved safety. | Requires dedicated infrastructure, can be expensive to implement. | High |

| Robotic Process Automation (RPA) | Software robots that automate repetitive tasks. | Improved accuracy, reduced errors, 24/7 operation. | Requires significant initial investment in software, needs careful planning. | Medium-High |

| Warehouse Management Systems (WMS) | Software systems that manage warehouse operations. | Improved inventory tracking, optimized order fulfillment. | Can be complex to implement and require specialized training. | Medium |

Technology Integration for Resilience

Navigating the turbulent waters of supply chain disruptions demands a proactive approach, and technology is no longer a luxury, but a necessity. Integrating advanced technologies into warehousing operations allows for greater flexibility, enhanced visibility, and a significant boost in resilience against future shocks. This proactive approach ensures businesses are better positioned to anticipate and respond to disruptions, mitigating their impact and maintaining operational efficiency.Warehouse management systems (WMS) have evolved significantly, moving beyond basic inventory tracking to encompass intricate supply chain management.

Modern WMS solutions now offer real-time visibility across the entire supply chain, facilitating better communication between different stakeholders and optimizing resource allocation. This allows for quicker adjustments to changing demand and supply dynamics, thus enhancing overall resilience.

Warehouse Management Systems (WMS) Evolution

Modern WMS solutions are built on sophisticated algorithms and data analysis capabilities. They offer features like automated order fulfillment, optimized picking routes, and real-time inventory tracking, all of which contribute to improved operational efficiency. These systems can also incorporate predictive analytics, allowing warehouses to anticipate potential disruptions and adjust their strategies accordingly. Furthermore, WMS are designed to be scalable, allowing businesses to easily adapt to changing volumes and demands.

Data Analytics for Efficiency

Data analytics plays a pivotal role in improving warehousing efficiency. By collecting and analyzing data from various sources, including inventory levels, order patterns, and transportation times, warehouses can identify trends, predict future demands, and optimize operational strategies. This approach allows for more efficient resource allocation, reduced lead times, and improved customer service. Real-world examples of this include Amazon’s use of data analytics to predict peak demand periods, allowing them to proactively adjust staffing and inventory levels.

Obtain recommendations related to cima ethics confidentiality rules that can assist you today.

Predictive Modeling in Warehouse Operations

Predictive modeling in warehousing goes beyond simple trend identification. It involves using historical data and machine learning algorithms to forecast future events, such as demand fluctuations, supply chain bottlenecks, or equipment failures. This proactive approach allows warehouses to prepare for potential disruptions, proactively adjusting staffing, inventory, and logistics plans. For instance, a warehouse experiencing seasonal demand fluctuations can use predictive modeling to anticipate peak periods and adjust staffing accordingly.

Robust Warehouse Security Protocols

Implementing robust warehouse security protocols is crucial for safeguarding inventory and personnel after disruptions. This includes advanced access control systems, real-time monitoring, and proactive threat detection mechanisms. Robust security protocols can help mitigate the risk of theft, damage, or unauthorized access, maintaining the integrity of operations. Furthermore, these protocols need to adapt to new threats and vulnerabilities.

Integration of Technologies in Warehousing

| Technology | Application in Warehousing |

|---|---|

| Internet of Things (IoT) | Real-time tracking of inventory, equipment monitoring, and predictive maintenance |

| Artificial Intelligence (AI) | Automated order fulfillment, optimized picking routes, and proactive risk management |

| Machine Learning (ML) | Predictive demand forecasting, anomaly detection, and automated decision-making |

| Cloud Computing | Scalable storage and processing of vast amounts of warehouse data, enabling real-time insights and faster response to disruptions |

Supply Chain Visibility and Collaboration

Navigating the complexities of modern supply chains, especially in the wake of disruptions like the pandemic and Brexit, requires a fundamental shift towards enhanced visibility and collaborative partnerships. Effective communication and shared information are crucial for proactively identifying and mitigating risks, ensuring resilient operations, and maintaining customer satisfaction. This approach fosters agility and adaptability, allowing businesses to respond swiftly to changing market conditions and emerging challenges.

Importance of Enhanced Supply Chain Visibility

Supply chain visibility provides a comprehensive understanding of the flow of goods and information throughout the entire process, from origin to consumer. This allows stakeholders to track inventory levels, monitor production progress, anticipate potential delays, and make informed decisions in real-time. In disrupted markets, enhanced visibility is paramount. The ability to quickly identify bottlenecks, predict potential shortages, and adjust strategies accordingly minimizes the impact of unforeseen events and allows businesses to maintain operational continuity.

It enables a proactive rather than reactive approach to managing supply chain disruptions.

Technology Facilitating Communication and Collaboration

Technology plays a critical role in facilitating better communication and collaboration between stakeholders in the supply chain. Real-time data sharing platforms, integrated software systems, and cloud-based communication tools enable seamless information exchange. These systems provide a centralized view of the entire supply chain, allowing stakeholders to access and share critical information instantly. This collaborative approach fosters a shared understanding of the current state of the supply chain, enabling stakeholders to work together to address challenges and capitalize on opportunities.

Blockchain Technology for Supply Chain Transparency

Blockchain technology offers a promising solution for enhancing supply chain transparency. Its decentralized and immutable nature ensures the authenticity and integrity of information throughout the process. By recording every transaction on a shared ledger, blockchain provides a verifiable and auditable trail of goods, enabling stakeholders to track the movement of products and materials from origin to destination. This level of transparency builds trust and accountability, reducing fraud and counterfeiting.

It enhances the traceability of products, enabling companies to respond quickly to product recalls or quality issues.

Do not overlook explore the latest data about finance departments evolving while bracing for coronavirus second wave.

Effective Communication Mitigating Risks

Effective communication is essential for mitigating risks in a disrupted supply chain. Regular communication channels, including meetings, alerts, and reporting mechanisms, enable stakeholders to share information about potential disruptions, risks, and solutions. Open communication fosters collaboration and allows for the rapid dissemination of crucial updates, allowing stakeholders to adapt to evolving situations and implement preventative measures. Clear communication protocols, including predefined escalation procedures, ensure that issues are addressed promptly and efficiently.

Successful Supply Chain Collaboration Strategies

Successful supply chain collaboration strategies are built on trust, transparency, and shared goals. Examples include collaborative forecasting, joint inventory management, and shared risk mitigation strategies. Companies that effectively share information and coordinate their efforts are better equipped to manage disruptions and maintain smooth operations. Collaboration between suppliers, manufacturers, distributors, and retailers can lead to optimized logistics, reduced lead times, and enhanced efficiency.

A strong focus on open communication channels and shared data ensures smooth and coordinated responses to unexpected events.

Examples of Successful Collaboration

Several companies have demonstrated successful supply chain collaboration strategies. For example, companies that integrated their systems to track shipments and inventory in real time have improved their ability to respond to disruptions. By sharing information about inventory levels and potential delays, these companies have been able to adjust their production schedules and shipping plans to minimize the impact of disruptions.

This collaborative approach has reduced lead times and enhanced overall efficiency.

Software Solutions for Supply Chain Visibility

| Software Solution | Key Features | Benefits |

|---|---|---|

| SAP Supply Chain Management | Integrated planning, execution, and monitoring tools | Improved visibility into all aspects of the supply chain, allowing for real-time adjustments to disruptions. |

| Oracle SCM Cloud | Cloud-based platform for supply chain management | Provides a centralized platform for all stakeholders to access and share data, improving collaboration and visibility. |

| Manhattan Associates | Advanced warehouse management and planning tools | Enhances warehouse efficiency and optimizes inventory management, improving responsiveness to disruptions. |

| Infor CloudSuite Industrial | Industry-specific supply chain solutions | Tailored solutions for various industries, helping them optimize their supply chains based on specific needs and challenges. |

Safety and Security Enhancements

Post-disruption, warehousing operations demand a renewed focus on safety and security. The evolving supply chain landscape, marked by workforce shifts and heightened vulnerabilities, necessitates robust protocols to mitigate risks and ensure smooth operations. Prioritizing employee well-being and safeguarding inventory are paramount to resilience.

Importance of Maintaining High Safety Standards

Maintaining high safety standards in warehousing is not just a matter of compliance; it’s a critical component of operational efficiency and employee well-being. Accidents and injuries can lead to significant downtime, lost productivity, and increased insurance costs. A safe workplace fosters a positive work environment, reduces employee turnover, and ultimately improves the bottom line. Moreover, a culture of safety instills trust and confidence in the workforce, making them more receptive to new procedures and technologies.

New Safety Protocols and Procedures for a Changing Workforce and Environment

Evolving workforce demographics and changing environmental factors necessitate updated safety protocols. These protocols should incorporate measures for diverse employee needs, including training for new hires and refresher courses for existing staff on new equipment and procedures. Adapting to potential shifts in environmental conditions (such as extreme temperatures or increased humidity) requires implementing appropriate protective gear and modifying work schedules.

Regular safety audits and inspections are essential for identifying and addressing potential hazards proactively.

Examples of Successful Warehouse Safety Programs

Numerous warehouse operations have successfully implemented safety programs that significantly reduced incidents. One example involves a company that implemented a comprehensive safety training program for all employees, coupled with regular safety audits and immediate corrective actions. Another successful program focused on hazard identification and risk assessment, using a multi-layered approach that included visual cues, written instructions, and designated safety personnel.

These initiatives not only lowered accident rates but also fostered a culture of proactive safety among employees.

Designing Security Measures to Protect Against Supply Chain Theft and Fraud

Implementing robust security measures is crucial to combat supply chain theft and fraud. This involves installing advanced surveillance systems, implementing stringent access controls, and utilizing real-time tracking technologies to monitor goods throughout the supply chain. Regular security assessments and audits are vital for identifying and addressing potential vulnerabilities. Utilizing sophisticated authentication systems and secure storage facilities for sensitive materials are key components of a robust security strategy.

Employing security personnel and implementing stringent background checks for employees with access to high-value or sensitive goods further bolsters security protocols.

Ensuring the Security of Sensitive Goods

Securing sensitive goods, such as pharmaceuticals, high-value electronics, or regulated materials, requires specialized protocols. These protocols may include secure storage facilities with controlled access, tamper-evident packaging, and real-time tracking systems to monitor location and condition. Encryption of data related to these goods and restricted access to sensitive information are also vital. The use of advanced security systems, such as biometric access control and advanced video surveillance, is critical for sensitive items.

Best Practices for Warehouse Safety and Security

| Category | Best Practice | Rationale |

|---|---|---|

| Safety | Regular safety training for all employees | Reduces accident risk by improving awareness and skillset. |

| Safety | Prompt reporting and investigation of near-miss incidents | Identifies potential hazards before they lead to accidents. |

| Security | Multi-layered security system (access control, surveillance, alarms) | Reduces vulnerability to theft and unauthorized access. |

| Security | Regular security audits and vulnerability assessments | Identifies and addresses weaknesses proactively. |

| Security | Secure storage for sensitive goods | Protects against loss, damage, or theft. |

| Safety | Ergonomic workstation design | Minimizes strain and injury, improving worker well-being. |

Epilogue: Managing Warehousing After Supply Chain Disruption Coronavirus Brexit

In conclusion, managing warehousing after the supply chain disruptions caused by COVID-19 and Brexit demands a multifaceted strategy. Adapting to changing customer demands, labor shortages, and supply chain bottlenecks requires a shift towards resilient operations, utilizing technology, optimizing inventory, and fostering strong communication and collaboration within the supply chain. By implementing the discussed strategies, warehouses can navigate future disruptions and maintain operational excellence.